How To Install Chimney Flashing On Metal Roof

Installing Chimney Flashing

Leak-proof your chimney using this traditional, time-tested flashing method.

![]() Fourth dimension

Fourth dimension

A full mean solar day

![]() Complexity

Complexity

Advanced

![]() Cost

Cost

$51–100

Introduction

This traditional, fourth dimension-tested flashing method guarantees a leakproof ready. Follow this step-by-stride procedure and you tin can set the leak and save $100s.

Tools Required

Materials Required

- 26-estimate galvanized sheet steel (for prefabricated pieces)

- Drive-in expanding anchors

- Galvanized curl stock

- Galvanized front base flashing

- Galvanized footstep flashing

- Polyurethane caulk

- Self-adhering roofing membrane (water ice and water barrier)

Chimney leaking? Look for flashing bug

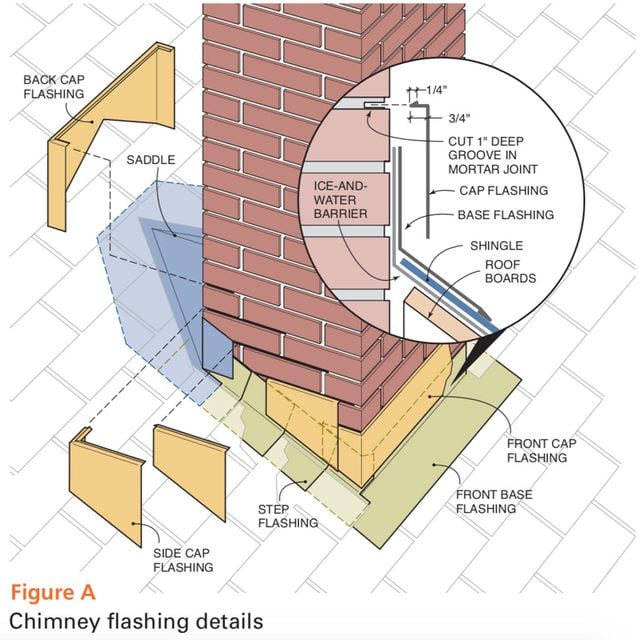

Effigy A: Chimney flashing details

Chimneys are notorious for leaking, and the culprit is almost always the sheet metal flashings. Simply inquire any roofer. But it doesn't take an good to spot problems—but await for water-stained ceilings or other telltale signs of leaking in the vicinity of your chimney. So what is placed around a chimney to forestall leaks?

You lot'll desire to install new chimney flashing if it's missing, rusted through, falling out or completely covered with roofing tar (a typical short-term set up that's sure to be hiding bigger problems). It's also a good time to install new flashing when y'all put on new shingles because you'll want information technology to terminal as long every bit the new roofing (25 to 40 years).

In this article, we'll tell you how to society new flashing and install it on a brick chimney. Our roof has asphalt shingles, just the procedure is the aforementioned for forest shingles. Slate and tile roofs require special flashing techniques that are all-time left to the pros. Flashing a chimney is an advanced DIY projection. For starters, you lot have to be comfortable working on a roof. Then yous take to measure, cut and bend canvas metal to fit precisely around the chimney and layer all the parts and then they shed water. Even so, if you lot're handy with tools and carefully follow our instructions and diagrams, you'll be able to flash your chimney in a day. And every bit far as chimney flashing repair price goes, by doing it yourself, you'll save hundreds of dollars.

Project step-by-stride (12)

Step 1

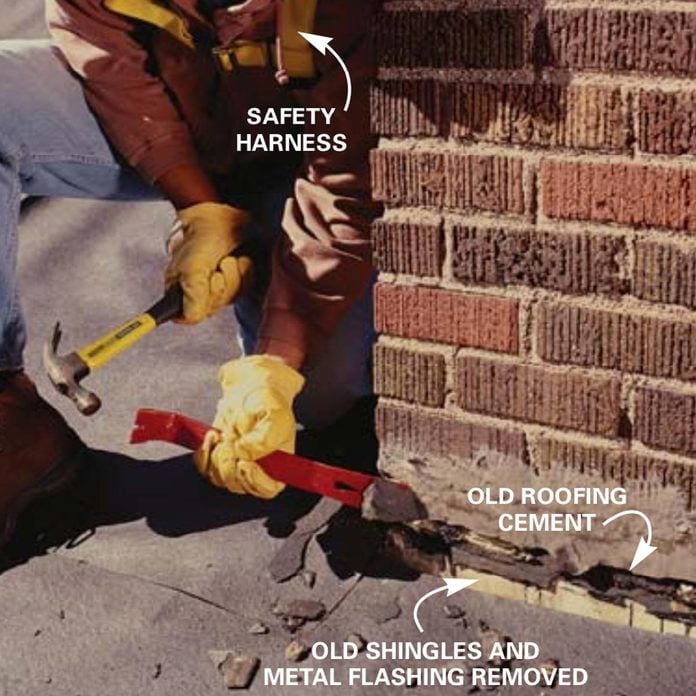

Get together all materials first, then remove sometime flashing

Pry, chisel and scrape off old metallic flashings and roofing cement.

Before y'all do annihilation, go your ladder, roof brackets and safety harness set up and so you can piece of work safely and efficiently on the roof. And then measure the chimney and gild the saddle and flashing parts (see "How to Buy Chimney Flashing," beneath).

Nosotros ordered all our 26-gauge galvanized metallic flashing aptitude to the correct angles and dimensions from a sheet metal shop specializing in covering. The store did a great job. I dropped off the dimensions and three days afterward the stuff was set up to selection upwardly. Even with the custom-made saddle, the flashing was inexpensive. In add-on to the flashing and shingles, buy a roll of self-adhering covering membrane (also chosen ice-and-water barrier), two tubes of polyurethane caulk, and a package of 25 bulldoze-in expanding anchors from a dwelling house eye or roofing shop.

Besides basic hand tools like a hammer, tape measure, 2-ft. level and square, you lot'll need a few special tools for working with canvas metal and cut and drilling masonry. Purchase a expert pair of straight-cutting tin snips, a 3/16-in. masonry flake and a grinder (a great excuse to buy this useful tool) or a circular saw fitted with a drycut diamond bract for grooving the mortar (Photo 7).

Don't forget safety equipment. You'll need a sturdy extension ladder to get on the roof, and roof brackets and pinnacle-quality 2x10 planks to piece of work safely one time y'all get at that place. For maximum condom, especially if the roof is steep or high, purchase a personal fall arrest arrangement consisting of a safety harness, lanyard, rope-grab, rope and roof anchor.

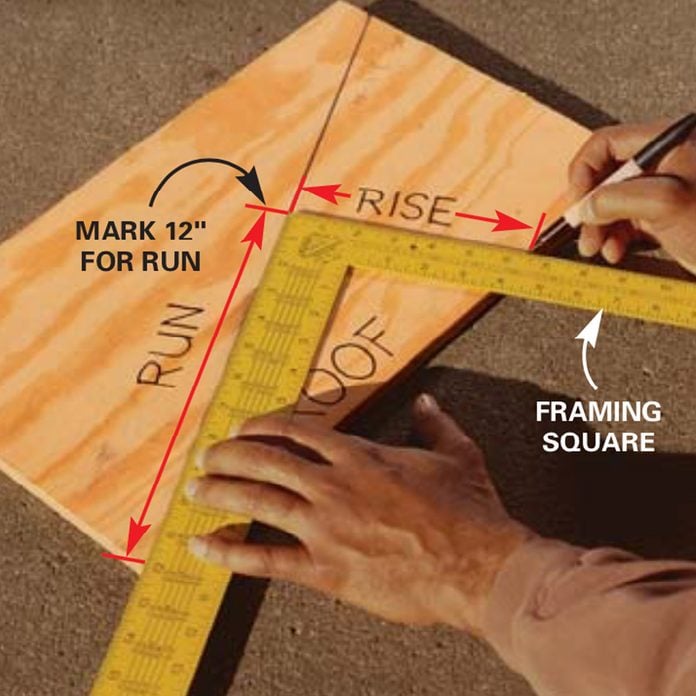

How to Discover Your Roof Slope

Find the slope of the roof. Label 1 edge of a ii-ft. square scrap of plywood or cardboard "roof" and lay the labeled edge against the roof. Draw a level line at to the lowest degree 12 in. long on the plywood and label the line "run."

Measure 12 in. along the "run" line and make a mark. Use a framing square to depict a square line from this marker downwardly to the edge of the plywood labeled "roof." Label this line "rise." Mensurate the length of the line labeled "rise" to make up one's mind the gradient, expressed as inches of rise for every 12 in. of run. In our case, the roof slope is half dozen in. of rise for every 12 in. of run.

Pace 2

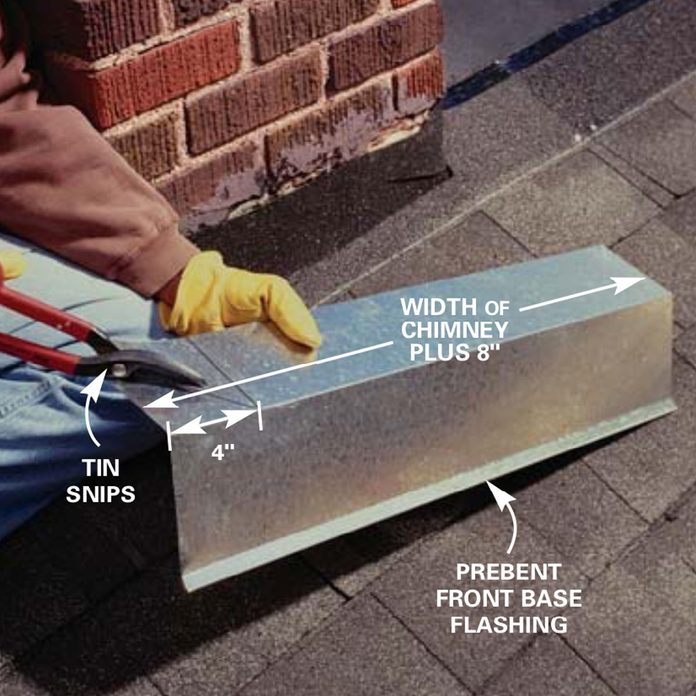

Cut base flashing, then attach the base flashing

Cut a piece of prebent base flashing to fit beyond the front of the chimney. Cut a 45-degree angle to bend effectually one side.

Step three

Install front base flashing

Snug this bent end confronting one side of the chimney front. Mark the edge of the chimney on the opposite end and snip and bend this cease. Pound four evenly spaced i-in. galvanized roofing nails through the front border of the flashing to hold it in place.

One time you complete the tearout and clean up, shingle up to the bottom of the chimney (Photo 2) and seal around information technology with 12-in. wide strips of ice-and-h2o bulwark. Lap the strips 4 in. up onto the bricks and overlap adjacent strips to shed water. Run a full 36-in.wide strip beyond the top of the chimney. Stick this piece to the roof boards and up 8 in. onto the back of the chimney. Later you'll seal the new metal saddle to this piece with boosted strips of the membrane then install roofing paper and shingles over the metal saddle.

Start the flashing job by installing the first piece of base flashing across the bottom of the chimney and over the acme of the shingles (Photo 3).

Step 4

Add step flashing and the chimney saddle: Install flashing effectually the corners

Snip and bend a slice of prebent viii-in. foursquare step flashing to fit 1-1/2 in. around the front corner as shown. Apply a jelly edible bean–size dollop of caulk at the corner where the chimney meets the roof. Embed the corner footstep flashing in the caulk and nail it to the roof with two roofing nails.

Stride five

Install flashing around the chimney

Nail the side by side shingle over the beginning step flashing. Then nail another step flashing over this shingle. Continue until you get to the top corner of the chimney. Cut and bend the last step flashing effectually the top.

Pace 6

Install the chimney saddle

Slide the prebent and soldered chimney saddle into place behind the chimney. Smash it to the roof along the height edge. Space 1-in. galvanized roofing nails about every 6 in. along the edges or closer if necessary to flatten the metal.

Seal the sides of the chimney with prebent pieces of stride flashing under each course of shingles (Photos four and 5). Slightly flatten the stride flashing before you nail it in to ensure a tighter, spring-tensioned fit against the chimney. Pay close attention to overlapping each slice of flashing onto the preceding one in such a manner that h2o is diverted over the acme of the shingles. This is the fundamental to a successful flashing job.

Complete the base flashing past nailing the saddle to the roof and sealing it with additional strips of membrane (Photo vi). Shingle over the portion of the saddle that rests on the roof and cut the shingles neatly forth the valley, leaving most two in. of metal exposed.

How to Purchase Chimney Flashing

Making precipitous, straight bends in sheet metal is catchy unless you have access to a tool called a sheet metal angle brake. Even so, you need experience to bend complicated shapes. That'southward why we're recommending that y'all order your chimney flashing from a sheet metallic fabricating shop. Large covering companies often take their ain sheet metal shops and are the best place to buy the chimney saddle and flashing; they'll know exactly what yous need. Otherwise, bank check the Xanthous Pages nether "Sheet Metal." We used 26-gauge galvanized sheet steel for our flashing and saddle, but prefinished steel or copper are other possibilities.

Virtually chimneys have a small rooflike structure behind them, called saddle (Photo 6), that diverts snow and h2o to both sides of the chimney. Whether your chimney has a wooden saddle covered with shingles, a sheet metal saddle or no saddle at all (like the chimney in this story), we recommend installing a new custom-made sheet metal saddle (Photograph 6).

Custom-made saddles are soldered together at critical spots that are difficult to seal on saddles that are built in identify. Soldered sheet metal saddles less than 3 ft. wide are cocky-supporting and easier to install if you lot just tear out any existing metal or wood saddle. Most old saddles were built right over the top of the roof boards and demand no patching. Otherwise, fill in the missing boards before installing the new saddle. Saddles wider than three ft. may demand boosted support. Ask your sheet metallic fabricator for advice.

Bending and soldering a saddle is complicated, but sheet metallic shops demand only ii pieces of data from yous to bend up a saddle: the width of the chimney and the slope of the roof (meet "How to Find Your Roof Gradient,").

In addition to the saddle, you lot'll need the following canvas metallic parts (meet Figure A):

- Front end base flashing. Gild virtually 12 in. more the width of the chimney. Some lumberyards stock a "dormer flashing" that will work in this location. You may accept to conform the bending by bending it to friction match your roof slope.

- Prebent stride flashing, eight x 8 in. Roofers call these "shingle tins". Y'all'll demand one for each shingle forth the edge of the chimney plus a few actress. Most lumberyards stock these.

- Front cap flashing and side cap flashing. Some sail metallic shops stock a flashing for this purpose, merely you'll probably have to have it made. Mensurate at the front end of the chimney from the roof to the tertiary mortar joint and add about an inch to decide the acme you'll need. The shape is relatively unproblematic, and then you lot could buy flat sheet metal, called "curlicue stock," and bend these yourself.

- Back cap flashing. This flashing is identical to the front and side cap flashing.

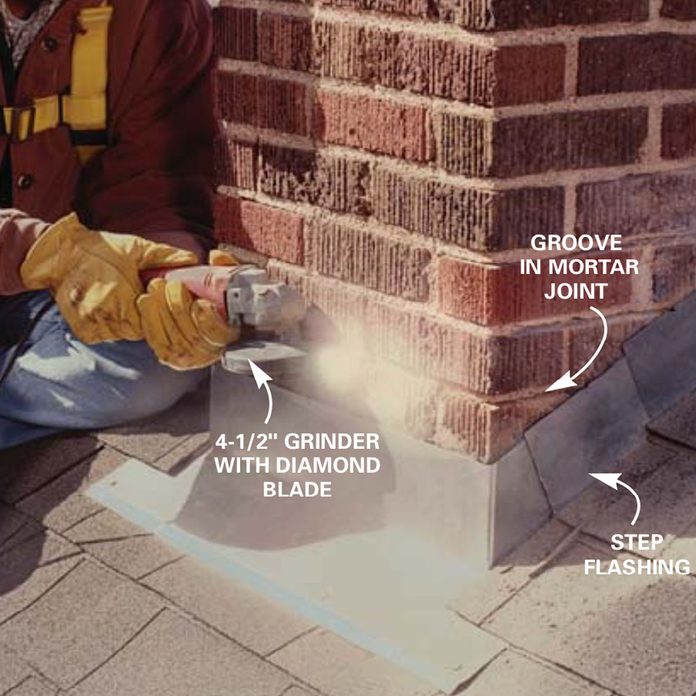

Step 7

Embrace the base of operations flashing with cap flashing: Saw grooves in the mortar

Saw i-in. deep grooves in the mortar joints to take the L-shaped cap flashing. See Figure A for help in locating the grooves. Use a dry out-cut diamond bract mounted in a grinder or a circular saw. Vesture goggles, hearing protection and a adept two-strap dust mask.

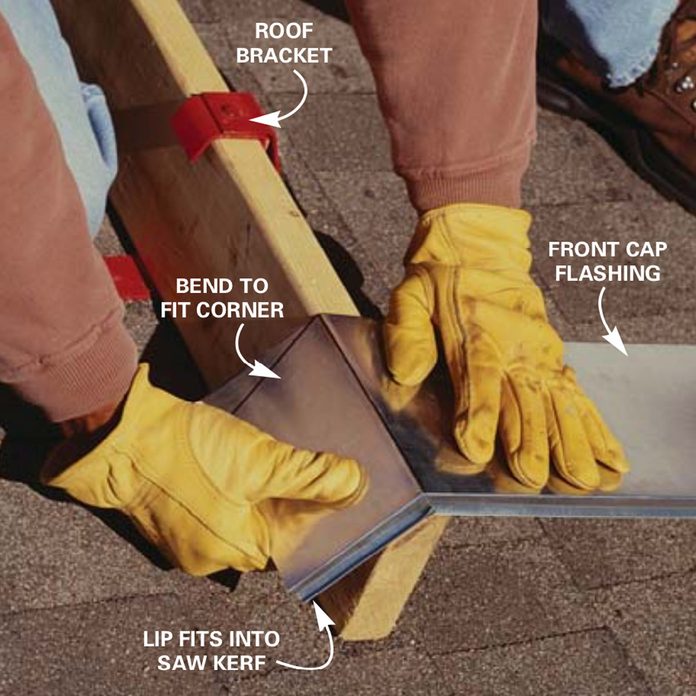

Step 8

Install the forepart cap flashing

Cutting the front end cap flashing 8 in. longer than the width of the chimney, so curve it around the forepart corners of the chimney.

Step 9

Drive in the flange

Drive the flange on the cap flashing into the groove in the mortar joint. Use a block of wood to keep from denting the flashing.

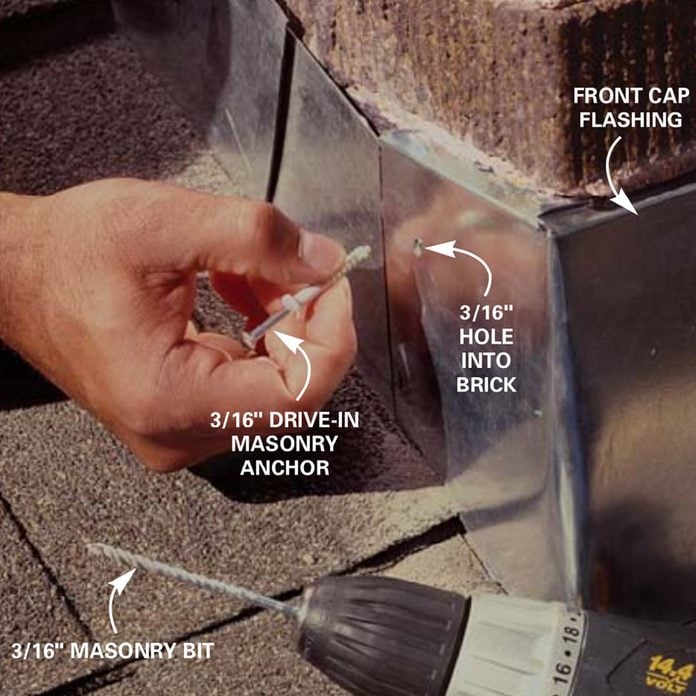

Stride 10

Secure the flashing

Drill a 3/xvi-in. x 1-1/2 in.-deep hole through the metallic and into the bricks on each corner of the chimney. And so press the expanding plastic anchors into the holes and pound in the protruding blast to aggrandize the anchor and secure the flashing.

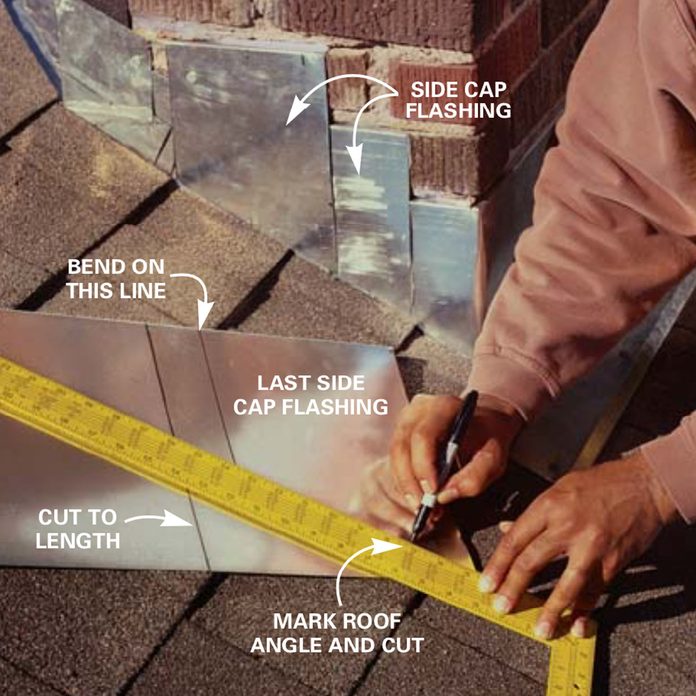

Stride 11

Go along to install cap flashing

Cut the side cap flashing to fit the bending of the roof so it overlaps each lower cap flashing at least 2 in. Pound the flashing into the grooves and spike with the drive-in expanding anchors. Bend a piece of cap flashing to fit effectually the top corner of the chimney and add the cap flashing across the back of the chimney.

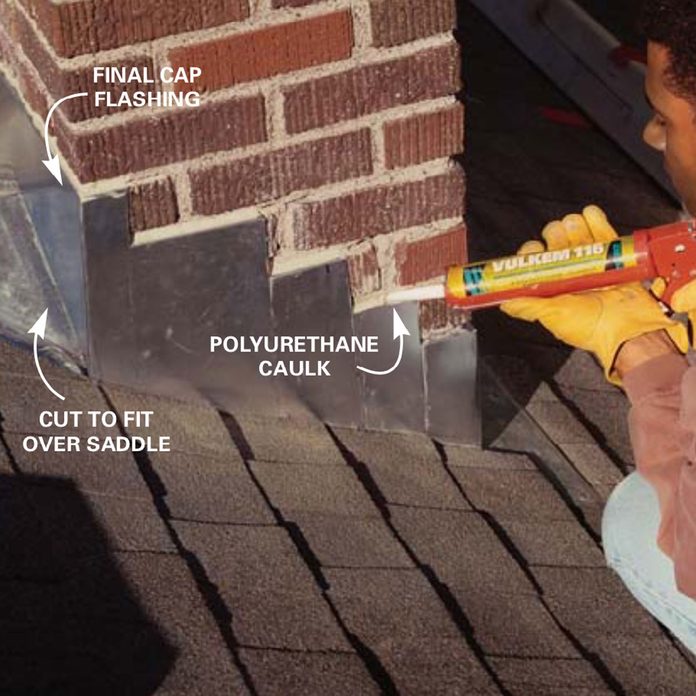

Step 12

Seal the flashing with caulk

Now it's fourth dimension for chimney flashing sealant. Seal the cap flashing by caulking along the mortar joint with polyurethane caulk.

The next step is to mark and cut the grooves in the chimney'south mortar joints to accept the cap flashing. Starting time at the front end of the chimney and mark the third mortar articulation up from the roof. Extend this mark around both front corners about 6 in. At present marking the mortar joints on the sides of the chimney then the flashing steps up until you reach the dorsum (Photograph 11). Depending on the slope of the roof, each footstep will leap upward ane or two mortar joints and should lap over the previous piece of flashing at least 4 in. Mark straight across the back of the chimney to cover the saddle (Photo 12).

Cutting the groove in the mortar is easiest with a grinder and a diamond blade (Photo vii). A circular saw with an cheap abrasive masonry blade will also work. Wearable goggles, a skilful dust mask and hearing protection. Cut shut to the brick on the lower edge of the mortar articulation. This way, the final caulk articulation volition exist less visible. Cut the slots near one in. deep and 1/viii in. wide. Make them a few inches longer than you think is necessary, keeping in mind that each piece of cap flashing has to overlap the 1 below it by most 2 in.

The little backward bend on the short leg of the cap flashing acts as a barb to hold the flashing in until you lot're ready to caulk. If the flashing is still loose, wedge it tight with a small plastic shim (sold every bit toilet shims in hardware stores and home centers) or secure it with expanding anchors every bit shown in Photo 10. Once all the cap flashings are in identify, complete the chore past filling the groove with polyurethane caulk (Photo 12).

Your new flashing volition concluding longer with a coat of paint. But don't pigment the bare galvanized metal without cleaning information technology first with lacquer thinner. Another option is to order the slightly more expensive prepainted metal flashing.

Source: https://www.familyhandyman.com/project/installing-chimney-flashing/

Posted by: coxrefort1949.blogspot.com

0 Response to "How To Install Chimney Flashing On Metal Roof"

Post a Comment